|

Products |

||||||||||||

|

Al Bilad HDPE & PP Profiled pipes Standards

|

|

|||||||||||

|

Material Specifications

HDPE/ PP-Profiled Piping System ( 300 mm to 4000 mm diameter )

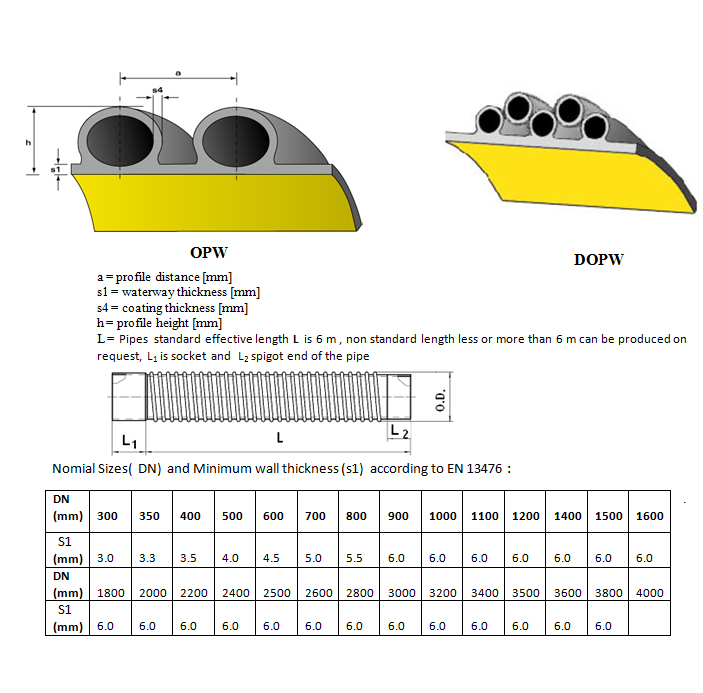

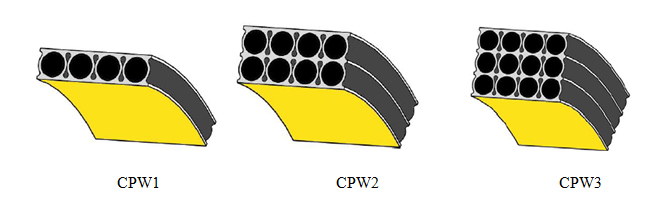

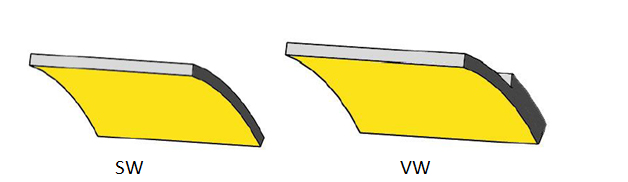

HDPE& PP pipes are manufactured in three different shapes according to the field of application and the purpose of use: 1- Series OPW : Single open profiled pipe (external profiled, internal smooth surface). 2- Series CPW : Close profiled pipe ( external and internal smooth surface). 3- Series DOPW : Double open profiled pipe (external profiled, internal smooth surface). 4- Series SW : solid pipe ( external and internal smooth surface). 5- Series VW : solid pipe ( external and internal smooth surface ).

Series CPW Pipes or so called closed pipes in HDPE/PP piping system are the pipes that are generally designed for the fabrication of manholes, storage tanks and reservoir for industrial applications. Although Series CPW Pipes are similar in major specifications to Series PW Pipes.

Series SW Pipes in HDPE/PP piping system for industrial applications are the pipes that have smooth internal and external wall surfaces without profiles. These pipes are used within the projects where high degree of strength is requested for fabrication of manholes, tanks and pipes.

HDPE/PP- Fittings

All fittings are fabricated from pipes of the type SW or VW. Generally the fittings are designed corresponding to the required stiffness and in consideration of the welding factors. Every fitting can have any kind of pipe end and any jointing techniques including the integrated Electro-Fusion socket and spigot. All pipe end dimensions fulfill the requirements of the EN 14376 standard, like minimum lengths and stiffness. The standard spigot length (Ls) is 140 mm and the standard socket length (Lm) is 140mm.

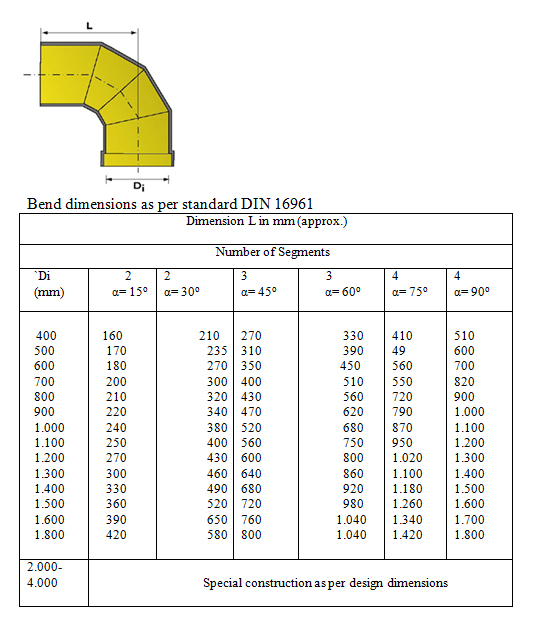

- Bends

Bends can be manufactured and segmented in different angles

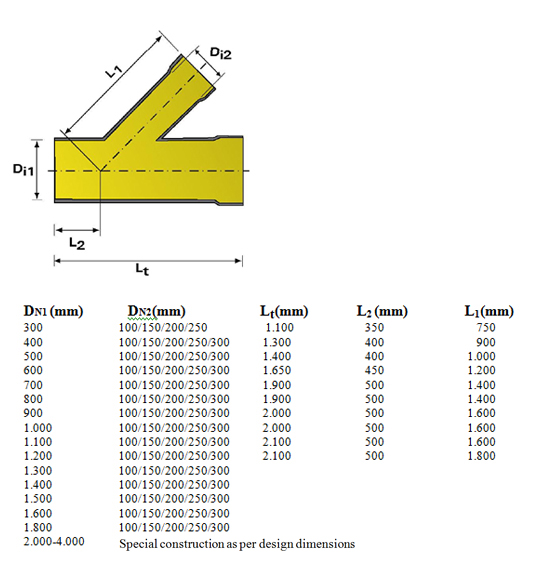

- Junctions

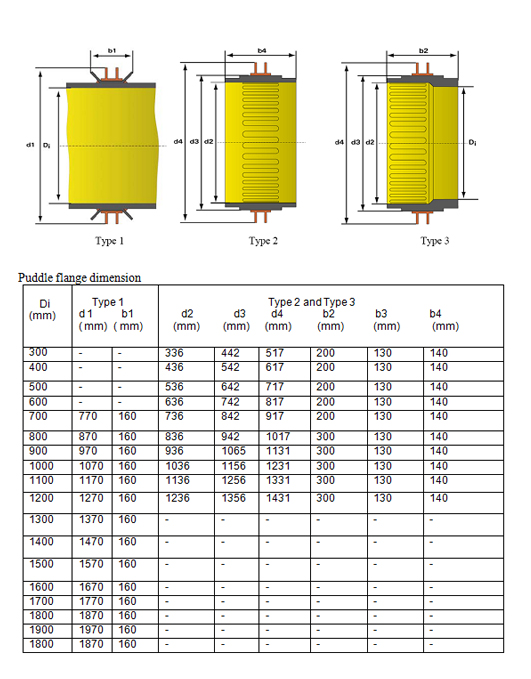

- Puddle Flange

In order to lead HDPE/PP pipes through walls, e.g. in sewage plants or concrete shafts, we recommend our puddle flanges which can be flush mounted in concrete. The tightness is secured by a ring made of

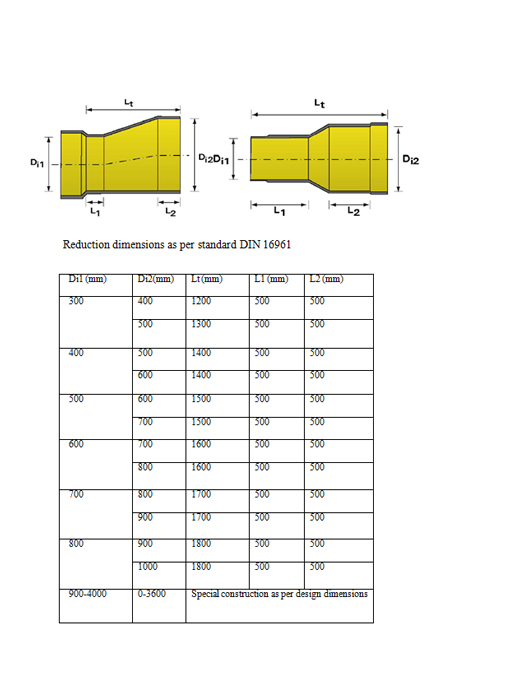

- Reducers

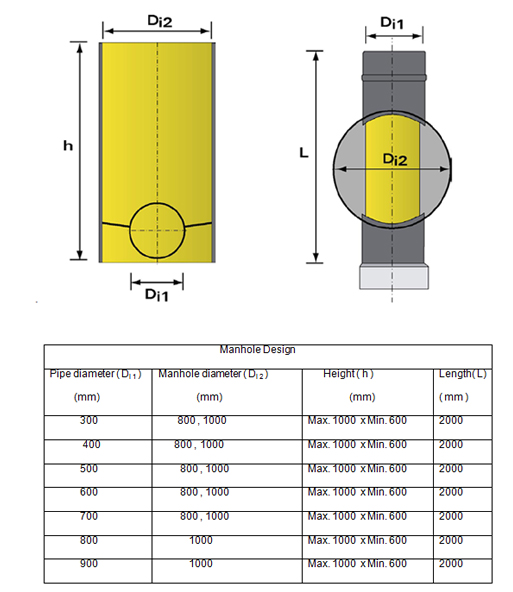

Manholes

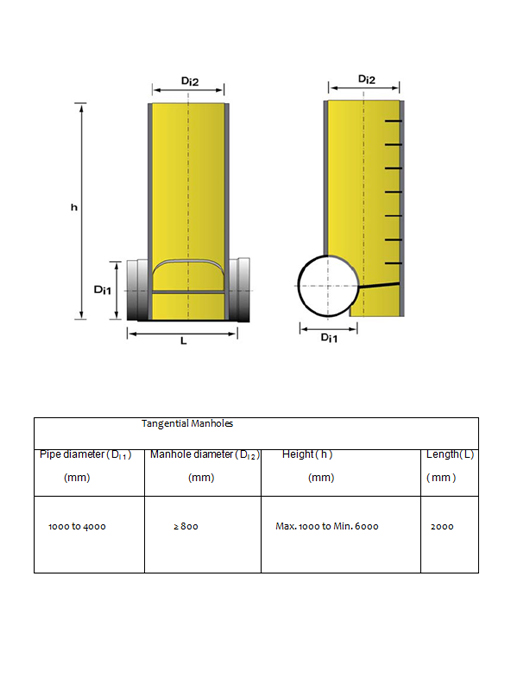

Tangential Manholes

|

|

|||||||||||

.

.